Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

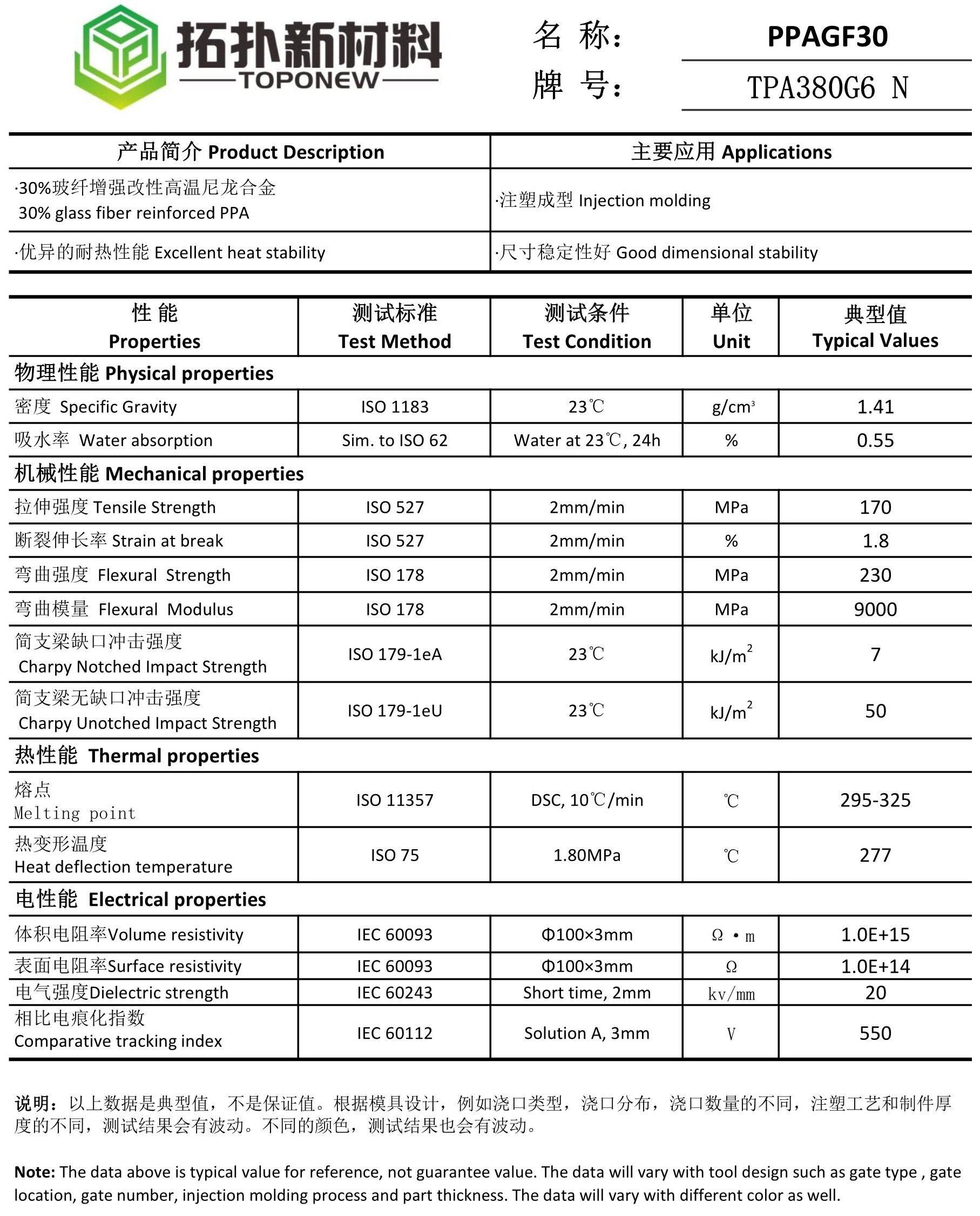

PPA TPA380G6N

Glass Filled: 30%

(Custom materials available according to your Technical Data Sheet)

- Detalle del producto

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Technical Data Sheet of PPA TPA380G6N

PPA TPA380G6N is a modified PPA granule (Polyacrylamide) that is reinforced with 30% glass fiber and complies with RoHS regulations. It is specifically designed for injection molding applications.

Featuring excellent high-temperature resistance, superior mechanical properties, and resistance to creep deformation, PPA TPA380G6N offers exceptional performance. It has a low water absorption rate and exhibits excellent dimensional stability. Additionally, it boasts outstanding electrical properties.

This PPA granule is widely used in industries such as electronics, electrical appliances, automotive, and more. It finds great suitability for components like micro switches due to its reliable performance and properties.

As a trusted Engineering Modified Plastic Manufacturer, TOPONEW is committed to producing high-quality PPA TPA380G6N PPA granules that meet the stringent requirements of various industries. By choosing this versatile material, businesses in electronics, electrical appliances, automotive, and related fields can benefit from its excellent performance and dependable solutions.

PPA (Polyphthalamide) is a high-performance engineering thermoplastic that offers a unique combination of properties suitable for various applications. Some common uses of PPA plastic include:

-

Automotive Components: PPA is widely used in the automotive industry for applications that require high heat resistance, chemical resistance, and dimensional stability. It is used for components such as connectors, sensors, fuel system parts, under-the-hood components, and air management systems.

-

Electrical and Electronics: PPA is used in electrical and electronic applications due to its excellent electrical insulating properties. It can be found in connectors, sockets, switches, circuit breakers, and other electronic components.

-

Industrial Equipment: PPA is used in industrial applications where high-performance plastics are required. It is used in pump components, valve bodies, gears, bearings, and other components that need to withstand harsh operating conditions.

-

Consumer Goods: PPA is used in the manufacturing of various consumer goods such as small appliances and tools where good mechanical properties and resistance to heat and chemicals are essential.

-

Medical Devices: PPA is used in the medical industry for applications requiring sterilization compatibility, chemical resistance, and durability. It can be found in medical instrument components, surgical tools, and device housings.

-

Aerospace Industry: PPA is suitable for aerospace applications that demand high performance under extreme conditions. It can be used in aircraft components, sensors, connectors, and other critical parts.

-

Water and Gas Handling Systems: PPA is used in water filtration systems, valves, fittings, and other components where resistance to chemicals and heat is necessary.

PPA plastics are chosen for their heat resistance, chemical resistance, dimensional stability, and mechanical strength, making them suitable for a wide range of demanding applications across various industries.

In chemistry, PPA typically refers to Phthalic Anhydride (PA) or to Phenylpropanolamine (PPA) depending on the context. Let me explain both:

- Phthalic Anhydride (PA):

- Phthalic anhydride is an organic compound commonly used in the production of phthalate esters, which are widely used as plasticizers in various polymer products.

- It is primarily used in the production of phthalate-based plasticizers for PVC (polyvinyl chloride) and other polymers to improve flexibility and durability.

- Phthalic anhydride is also used in the production of alkyd resins for coatings, as a precursor in the synthesis of pharmaceuticals, and as a reagent in organic synthesis.

- Phenylpropanolamine (PPA):

- Phenylpropanolamine, also known as PPA, is a sympathomimetic agent that acts as a decongestant and appetite suppressant.

- PPA was commonly used in over-the-counter cold and cough medications as a nasal decongestant, but its use has been largely discontinued due to safety concerns.

- PPA has stimulant properties and was once used in some weight-loss products and appetite suppressants. However, it has been banned in many countries due to the risk of stroke associated with its use.

Please provide more context if you are referring to a different chemical with the abbreviation "PPA" so I can provide you with more specific information.

Download

-

PPAGF30 TPA380G6 N BK.pdf

Download PPAGF30 TPA380G6 N BK.pdf